In modern manufacturing and packaging industries, efficiency, continuity, and precision are critical to maintaining high production standards. One challenge many production lines face is the interruption caused by manual label changes, which can slow down operations, increase labor costs, and risk errors. The SANTUO automatic uninterrupted label change workstation offers a revolutionary solution, enabling seamless label replacement without halting production, boosting both productivity and operational reliability.

What is an Automatic Uninterrupted Label Change Workstation

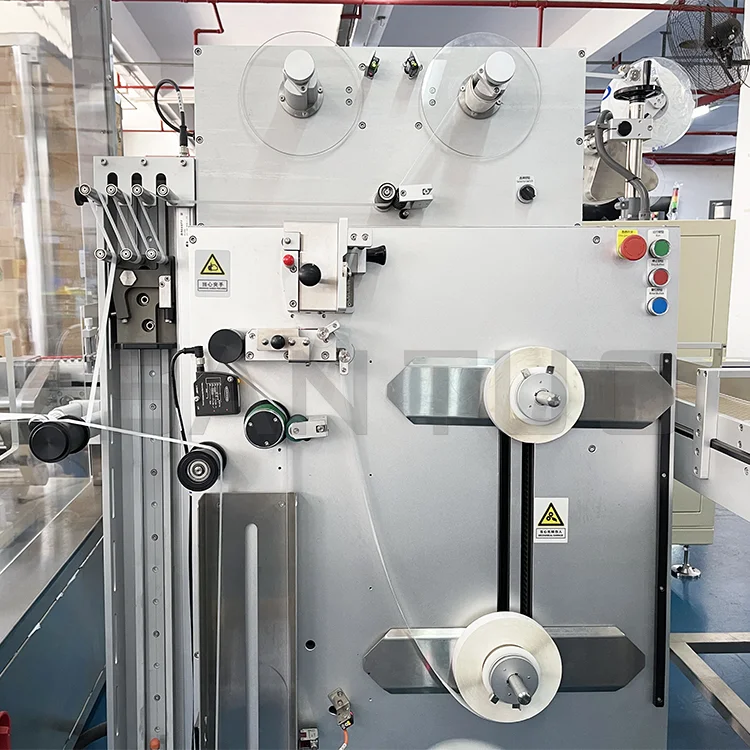

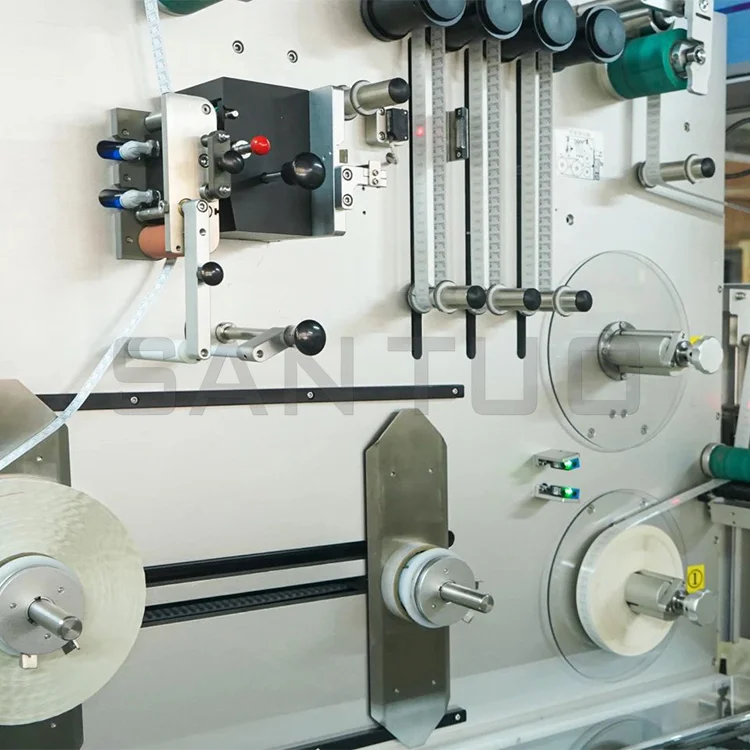

The automatic uninterrupted label change workstation is a highly intelligent labeling solution designed to enable continuous operation on production lines. Unlike traditional labeling setups that require manual intervention, this workstation allows pre-installed labels to be automatically switched between bins or reels, ensuring the production line never stops.

By integrating advanced mechanical interfaces and automation control systems, the workstation supports rapid adaptation to varying production requirements without modifying existing equipment structures. This makes it a versatile and highly compatible solution for industries that demand uninterrupted labeling efficiency.

Key Features of the Automatic Uninterrupted Label Change Workstation

Pre-Installed Labels and Automatic Switching

Labels are loaded in advance, reducing downtime during replacement.

When one bin (e.g., bin A) is full, the system automatically switches to the next bin (bin B) without halting production.

No Equipment Modification Required

Quick installation via standardized mechanical interfaces ensures seamless integration.

Compatible with a wide range of labeling machines and production line layouts.

Continuous, Uninterrupted Operation

Eliminates production stoppages caused by manual label changes.

Workers only need to collect full bins periodically, allowing the line to operate continuously.

Rapid Adaptation to Production Needs

Flexible design accommodates different label sizes, materials, and production speeds.

Ideal for high-volume or variable product lines.

Enhanced Operational Efficiency

Reduces labor intervention and human error.

Maximizes uptime and throughput on automated labeling lines.

Applications of the Automatic Uninterrupted Label Change Workstation

The automatic uninterrupted label change workstation is highly versatile and finds applications across multiple industries where labeling is a critical part of production:

1. Pharmaceutical Industry

Maintains uninterrupted labeling of medicine bottles, syringes, and medical packaging.

Ensures compliance with strict labeling and traceability standards.

2. Food and Beverage Industry

Supports continuous labeling of bottles, cans, and packaged goods.

Reduces downtime, ensuring faster delivery and consistent packaging quality.

3. Cosmetic and Personal Care Products

Efficiently handles frequent label changes across multiple product variants.

Guarantees high-speed labeling without manual intervention.

4. Electronics and Consumer Goods

Applies labels to components, boxes, and devices in assembly lines.

Reduces errors and ensures consistent branding and traceability.

5. Industrial and Chemical Products

Enables labeling of drums, containers, and other bulk items without halting production.

Maintains accuracy and operational continuity in heavy-duty industrial environments.

Advantages of Using an Automatic Uninterrupted Label Change Workstation

Zero Production Line Interruption

Automatic switching ensures continuous operation, eliminating costly downtime.

Reduced Labor Costs and Effort

Minimizes manual label replacement tasks.

Workers only need to collect full bins periodically, allowing staff to focus on other critical tasks.

High Compatibility and Flexibility

Integrates easily with existing labeling machines without modifying equipment.

Supports a wide range of production line configurations.

Improved Operational Accuracy

Reduces human error and mislabeling.

Ensures consistent and precise application of labels across products.

Rapid Installation and Adaptation

Standardized mechanical interfaces enable quick setup.

Adjusts easily to different production speeds, label types, and line requirements.

Enhanced Productivity

Continuous operation increases throughput.

Maximizes return on investment by optimizing both machine utilization and labor efficiency.

Conclusion

The SANTUO automatic uninterrupted label change workstation is a breakthrough solution for modern manufacturing and packaging industries, offering continuous labeling without production interruptions. With features like pre-installed labels, automatic switching, and quick integration via standardized mechanical interfaces, it delivers exceptional efficiency, reliability, and flexibility.

For businesses looking to optimize labeling processes, reduce downtime, and improve operational accuracy, the automatic uninterrupted label change workstation is an indispensable tool that combines intelligent design with practical functionality.