In today’s fast-evolving manufacturing landscape, achieving high precision and complex geometries in materials has become an essential requirement across industries such as aerospace, automotive, electronics, and medical devices. One technology at the forefront of these precision operations is wire-cutting, a process that transforms intricate designs into reality with unparalleled accuracy. For manufacturers seeking advanced solutions, understanding the wire-cutting parts class is vital to unlock the full potential of modern fabrication.

Leading the way in high-precision wire-cutting technology is AICHI TECHNOLOGY, a company renowned for its innovation, engineering expertise, and commitment to delivering parts that meet the most demanding specifications. With applications ranging from metals to composite materials, AICHI TECHNOLOGY provides manufacturers with solutions that traditional machining tools often cannot achieve.

1. Understanding the Wire-Cutting Process

Unlike conventional cutting methods that rely on physical blades, wire-cutting technology uses a ‘precision electric wire saw’ technique. The process involves the use of a thin wire through which an electrical current passes, creating controlled sparks that erode material at the cutting interface. This method allows for:

High-precision cuts: Achieving tolerances that are difficult or impossible with mechanical cutting.

Complex geometries: Including intricate shapes, narrow slots, and deep cavities.

Minimal mechanical stress: Ideal for brittle, hardened, or delicate materials.

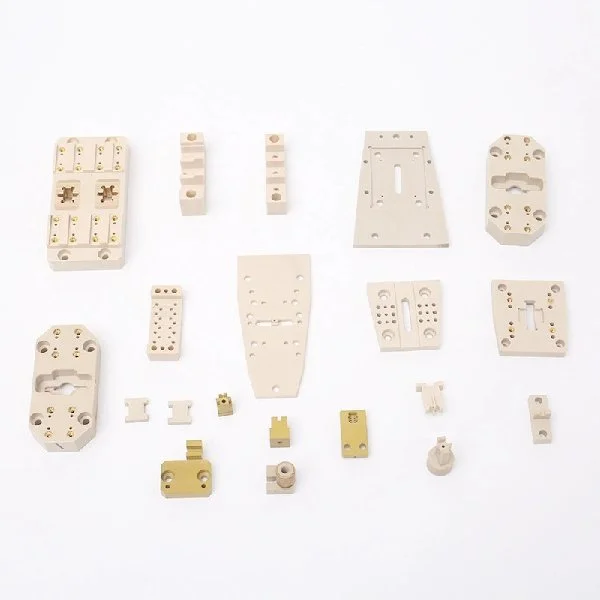

This technology is commonly used in the production of components requiring exacting specifications, such as aerospace brackets, medical device components, die sets, and precision molds.

2. Materials Suitable for Wire-Cutting

Wire-cutting is remarkably versatile. At AICHI TECHNOLOGY, the process is applied to a wide range of materials, including:

Common metals: Steel, aluminum, copper, and brass.

Special hard alloys: Tool steel, Inconel, titanium, and other high-strength alloys.

High-speed steel: Used extensively in cutting tools and dies.

Plastics and rubber: Including high-performance thermoplastics and elastomers.

Ceramics and composites: Ideal for electrically conductive or difficult-to-machine materials.

The ability to handle such diverse materials positions wire-cutting as a critical technology for high-mix, low-volume, and custom part production.

3. Advantages of Wire-Cutting for Precision Manufacturing

Wire-cutting technology provides multiple benefits for modern manufacturers:

3.1 Exceptional Accuracy and Repeatability

By relying on spark erosion rather than mechanical force, wire-cutting ensures minimal deviation and high dimensional stability. This is particularly valuable in aerospace and medical industries, where tolerances often fall within microns.

3.2 Capability for Complex Geometries

Conventional tools struggle with intricate patterns, narrow slots, and irregular contours. Wire-cutting excels in producing:

Curved slots and profiles

Micro-sized holes

Deep cavities with uniform surfaces

3.3 Reduced Material Stress

Traditional machining can introduce stress, deformation, or micro-cracks. Wire-cutting minimizes thermal and mechanical stress, preserving material integrity.

3.4 Surface Finish Quality

Wire-cut parts typically exhibit smooth edges with minimal post-processing required, reducing manufacturing time and cost.

4. Applications Across Industries

Aerospace & Defense

Critical components such as turbine blades, brackets, and custom assemblies benefit from the high-precision capabilities of wire-cutting, where tight tolerances are essential for performance and safety.

Medical Devices

Wire-cutting enables the manufacture of surgical instruments, implants, and specialized medical equipment parts with smooth surfaces and complex geometries.

Automotive

Precision dies, engine components, and transmission parts are increasingly produced using wire-cutting to ensure high accuracy and reduced material waste.

Electronics & Semiconductors

Components for microelectronics, circuit boards, and semiconductor fabrication demand the precise cuts and tolerances achievable through wire-cutting.

Tool and Die Making

Wire-cutting is instrumental in producing molds, dies, and other tooling components where intricate shapes and precision are critical.

5. AICHI TECHNOLOGY: Setting the Standard in Wire-Cutting Parts

At AICHI TECHNOLOGY, the wire-cutting process is integrated with advanced automation, quality control, and engineering expertise to produce parts that meet global standards. Key highlights include:

Customizable production: Ability to handle small to large batch production with high precision.

Advanced equipment: CNC wire-cutting machines capable of multi-axis control for complex parts.

Quality assurance: Rigorous inspections and adherence to ISO standards for dimensional and surface accuracy.

Innovation-driven solutions: Continuous R&D to enhance cutting efficiency, material compatibility, and surface finish quality.

Through these capabilities, AICHI TECHNOLOGY helps clients reduce production costs, shorten lead times, and achieve superior product performance.

Conclusion

Wire-cutting technology has revolutionized the manufacturing of precision and complex components, offering unparalleled versatility, accuracy, and surface quality. The wire-cutting parts class spans applications in aerospace, medical, automotive, electronics, and tooling industries—delivering solutions that traditional machining methods cannot achieve. With AICHI TECHNOLOGY leading the way in engineering expertise, automation, and quality control, manufacturers can confidently rely on wire-cutting for high-performance, cost-effective, and intricate parts production.

For companies seeking to maintain a competitive edge through precision, reliability, and innovation, investing in wire-cutting technology and collaborating with industry leaders like AICHI TECHNOLOGY is a strategic decision that enhances both product quality and operational efficiency.

https://www.wxaichi.com/redefining-precision-the-power-of-wire-cutting-parts-class.html