In the rapidly evolving solar energy industry, the performance and reliability of photovoltaic (PV) modules are paramount. Defects in solar cells or battery strings can significantly impact module efficiency, longevity, and overall system yield. To address this, advanced inspection and rework technologies have become essential. Among these, the Solar String Cell Test and Repair Station stands out as a high-precision solution designed to enhance manufacturing quality and operational reliability.

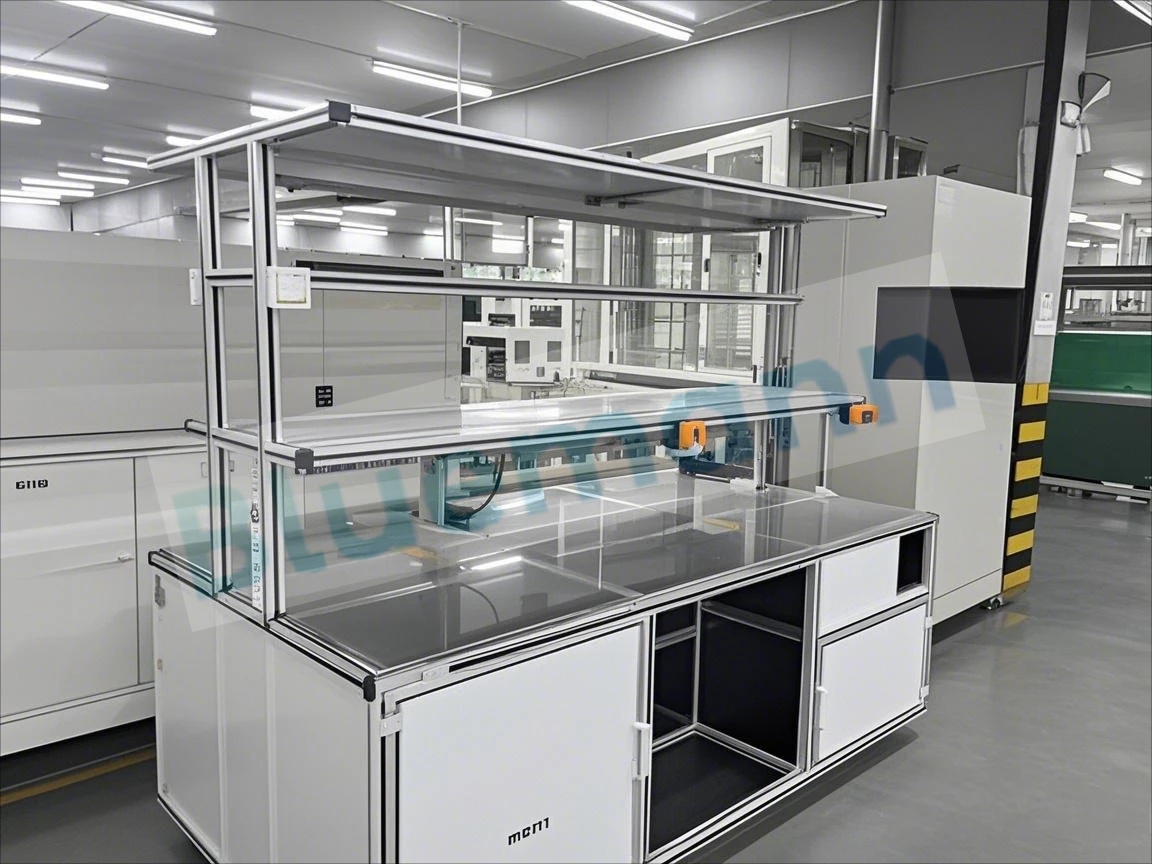

Bluemann, a leading innovator in solar manufacturing equipment, has engineered this system to provide accurate defect detection, precise localization, and efficient rework for solar modules, helping manufacturers achieve higher yields and improved long-term performance.

1. What Is a Solar String Cell Test and Repair Station

A Solar String Cell Test and Repair Station is specialized equipment used in the production and maintenance of photovoltaic modules. It focuses on battery strings, which are series-connected solar cells forming the core electrical structure of PV modules.

Key functionalities include:

Detecting micro-cracks and broken finger lines in solar cells

Identifying fragmented or chipped cells

Locating soldering flaws in series connections

Enabling precise rework of defective cells without damaging adjacent components

By integrating both inspection and repair in a single system, this station ensures that only fully functional battery strings are assembled into final modules, reducing waste and enhancing reliability.

2. High-Precision Inspection Capabilities

The reliability of PV modules largely depends on the quality of individual cells and their interconnections. Bluemann’s Solar String Cell Test and Repair Station incorporates state-of-the-art sensors and imaging technologies to detect even subtle defects.

Key inspection features:

Micro-Crack Detection: Identifies hairline cracks invisible to the naked eye, which could compromise module efficiency and lifetime.

Finger Line Monitoring: Detects broken or incomplete conductive lines that reduce current flow.

Fragment Identification: Locates small fragments or chips in cells that may affect voltage consistency.

Soldering Flaw Analysis: Examines welds between cells for weak or broken joints.

With this level of precision, operators can prevent defective cells from progressing down the assembly line, maintaining the highest quality standards.

3. Precise Localization and Rework

Beyond detection, the system provides accurate localization of defects, allowing for targeted rework without disturbing healthy cells. This capability is critical in maintaining both efficiency and yield.

Rework functionalities include:

Marking defective cells within the string for repair

Automated or semi-automated soldering corrections

Real-time feedback to adjust repair processes

Ensuring repaired cells meet stringent electrical and mechanical standards

By combining inspection and repair in a single workflow, the station reduces module rejection rates and maximizes material utilization, offering a significant advantage for PV manufacturers.

4. Enhancing PV Module Yield and Reliability

Defective cells not only lower immediate production yield but also risk long-term module degradation. By employing a Solar String Cell Test and Repair Station, manufacturers can achieve:

Higher First-Pass Yield: Early detection prevents defective cells from entering module assembly.

Improved Module Performance: Corrected defects ensure consistent electrical characteristics across the string.

Extended Module Lifetime: Prevents latent failures caused by micro-cracks or soldering issues.

Reduced Warranty Claims: Enhances customer confidence by delivering more reliable modules.

Bluemann’s solution integrates seamlessly into PV production lines, offering scalable inspection and repair capabilities for both small-scale and high-volume operations.

5. Applications in Manufacturing and Maintenance

This advanced station is applicable across multiple solar industry scenarios:

PV Module Production: Inline or offline quality assurance for new modules.

Module Refurbishment: Repairing returned or damaged modules to restore performance.

R&D and Testing: Evaluating new cell designs or materials for defect susceptibility.

By facilitating precise inspection and rework, the system supports continuous improvement in solar manufacturing processes.

6. Conclusion

In a competitive solar market, ensuring the quality and reliability of photovoltaic modules is crucial. The Solar String Cell Test and Repair Station from Bluemann provides manufacturers with a comprehensive solution for high-precision inspection, targeted defect repair, and enhanced module yield. Through its integration of advanced detection and rework capabilities, this system helps the solar industry produce durable, high-performance modules while minimizing waste and improving customer satisfaction.