In modern metalworking and fabrication environments, hole-making is no longer a simple drilling task. It is a precision-driven process involving tight tolerances, material diversity, production speed requirements, and strict safety standards. While hole-making machines—such as drilling machines, magnetic drills, and CNC machining centers—form the foundation, Hole-making Machine Auxiliary Tools are what determine actual performance, stability, and operational efficiency.

Understanding Hole-Making Machine Auxiliary Tools

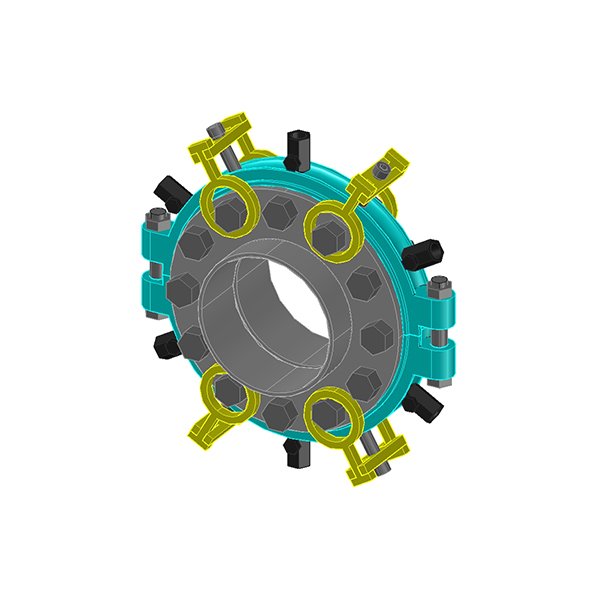

A Hole-making Machine Auxiliary Tool refers to any supporting device or attachment designed to enhance the performance, accuracy, and safety of hole-making operations. These tools do not replace the main machine; instead, they optimize its effectiveness under real-world production conditions.

Common categories include:

Positioning and alignment accessories

Clamping and fixation systems

Cutting guidance and stabilization tools

Chip removal and cooling aids

Tool change and depth control components

When properly selected and integrated, these tools significantly reduce error rates and improve throughput.

Core Functions in Industrial Machining

1. Precision Alignment and Positioning

Misalignment is one of the most frequent causes of poor hole quality, tool breakage, and scrap. Auxiliary alignment tools ensure:

Accurate positioning of the cutting axis

Consistent hole center placement

Reduced deviation in deep or angled drilling

In high-precision industries, even minor misalignment can result in assembly failure. Northen designs auxiliary tools that maintain positional integrity under vibration and load.

2. Stability and Vibration Control

Hole-making processes generate axial and radial forces that can destabilize the workpiece or cutting tool. Auxiliary stabilization tools help:

Reduce chatter during drilling

Improve surface finish inside the hole

Extend tool life by minimizing stress

This is particularly critical when working with hard alloys, thick plates, or stacked materials.

3. Controlled Clamping and Fixation

Secure workpiece fixation is essential for both safety and dimensional accuracy. High-quality Hole-making Machine Auxiliary Tools provide:

Uniform clamping force distribution

Rapid setup and release

Compatibility with various workpiece geometries

Northen’s auxiliary clamping solutions are engineered to balance holding strength with ease of operation, reducing setup time without sacrificing reliability.

Supporting Efficiency in High-Volume Production

Reducing Setup and Downtime

Auxiliary tools designed for quick alignment and repeatability allow operators to:

Shorten machine setup cycles

Maintain consistent hole positioning across batches

Minimize machine idle time

In production environments, these incremental time savings translate into significant cost advantages.

Improving Tool Life and Cost Control

Poor chip evacuation and inadequate cooling are leading causes of premature tool wear. Auxiliary systems that assist with:

Chip guidance and removal

Coolant delivery optimization

help maintain cutting efficiency and reduce tooling expenses over time.

Applications Across Industries

Hole-making Machine Auxiliary Tools are widely used in:

Structural steel fabrication

Shipbuilding and offshore engineering

Rail and bridge construction

Heavy equipment manufacturing

Energy and power infrastructure projects

Each application presents unique challenges related to material thickness, orientation, and accessibility—challenges best addressed through purpose-designed auxiliary tooling.

Engineering Considerations When Selecting Auxiliary Tools

A professional approach to auxiliary tool selection considers:

Compatibility with existing hole-making machines

Material type and thickness

Required hole tolerance and depth

On-site working conditions

Northen provides application-oriented auxiliary tools designed to integrate seamlessly with a wide range of hole-making equipment, reducing the need for custom modifications.

Why Choose Northen

As a trusted supplier in industrial tooling solutions, Northen focuses on functional reliability, structural durability, and practical usability. Its Hole-making Machine Auxiliary Tools are developed with direct input from real-world machining environments.

Key advantages include:

Robust materials suitable for heavy-duty applications

Precision-engineered interfaces for stable operation

Long service life under repetitive industrial use

Adaptability to different machines and jobsite conditions

Rather than offering generic accessories, Northen emphasizes performance-driven solutions that address real production challenges.

Conclusion

While often overlooked, Hole-making Machine Auxiliary Tools play a critical role in determining machining success. They bridge the gap between machine capability and real-world operating conditions, ensuring accuracy, safety, and efficiency.

With its engineering-driven approach and commitment to practical performance, Northen delivers auxiliary tooling solutions that empower manufacturers and contractors to achieve consistent, high-quality hole-making results across demanding industrial applications.